CONVERT IT!

Don't Sell your Diesel GENERATOR !

Diesel + GAS

Dual Fuel Conversion

Benefits:

- Run Diesel Generator on Dual Fuel (Diesel + GAS)

- Cut-down Genset Fueling + OpEx Budget By 30% - 50% with CNG

- Reduce emissions - NOx by 60%, COx by 10% and Particle Pollution by 50%.

- Up to 70% of Diesel Safely Displaced By CNG

- Supports 30KVA to 2,500KVA Diesel Generators

OUR PATH TO DECARBONIZATION

CONVERT IT!

Don't Sell your Diesel GENERATOR!

Diesel + GAS

Dual Fuel Conversion

Benefits:

- Run Diesel Generator on Diesel + CNG

- Save 30% - 50% on Gen Fueling + OpEx

- Reduce Air Pollution by Upto 60%

- Up to 70% of Diesel Displaced By CNG

- Supports 30KVA to 2,500KVA Gensets

OUR PATH TO DECARBONIZATION

How Does Dual Fuel Technology Work?

GasGen Dual Fuel solution involves an internal combustion of two types of fuels concurrently, usually diesel in conjunction with a natural gas in a combustion engine. It comprise of CNG-specific components that can be retrofitted on existing high speed diesel engines to allow the use of a mixture of Methane Rich Gas (most often Compressed Natural Gas or LPG) with Diesel as fuel. This Dual Fuel technology converts a diesel-powered generator into a generator that runs on both Compressed Natural Gas (CNG) or LPG and Diesel simultaneously. After conversion, the genset can switch seamlessly between diesel-only mode and dual fuel operations whenever CNG or LPG supply is detected. Moreso, the genset can also resume operating with 100% diesel only if the gas supply is cut-off or not available preventing unwanted disruptions and downtime. However, it is worthy of note that a ‘Gas only’ operation is not possible with this kind of conversion.

During Dual Fuel operation, the quantity of diesel intake can drastically be reduced to 30% and acts as the ignition source for the air-gas mixture. This significant proportion of Diesel displacement is replaced by upto 70% of CNG to produce equivalent heat energy during combustion in the cylinder.

And in fact, our technology enables diesel generators to safely operate on up to 70% natural gas across loads, and hugely reducing diesel consumption and maintenance costs generally. The emissions from such converted engines see substantial level of reduction. In the current market reality, these would imply a significant reduction in cost of running your diesel generators, i.e. lower OpEx.

How Does Dual Fuel Technology Work?

GasGen Dual Fuel solution involves an internal combustion of two types of fuels concurrently, usually diesel in conjunction with a natural gas in a combustion engine. It comprise of CNG-specific components that can be retrofitted on existing high speed diesel engines to allow the use of a mixture of Methane Rich Gas (most often Compressed Natural Gas or LPG) with Diesel as fuel. This Dual Fuel technology converts a diesel-powered generator into a generator that runs on both Compressed Natural Gas (CNG) or LPG and Diesel simultaneously. After conversion, the genset can switch seamlessly between diesel-only mode and dual fuel operations whenever CNG or LPG supply is detected. Moreso, the genset can also resume operating with 100% diesel only if the gas supply is cut-off or not available preventing unwanted disruptions and downtime. However, it is worthy of note that a ‘Gas only’ operation is not possible with this kind of conversion.

During Dual Fuel operation, the quantity of diesel intake can drastically be reduced to 30% and acts as the ignition source for the air-gas mixture. This significant proportion of Diesel displacement is replaced by upto 70% of CNG to produce equivalent heat energy during combustion in the cylinder.

And in fact, our technology enables diesel generators to safely operate on up to 70% natural gas across loads, and hugely reducing diesel consumption and maintenance costs generally. The emissions from such converted engines see substantial level of reduction. In the current market reality, these would imply a significant reduction in cost of running your diesel generators, i.e. lower OpEx.

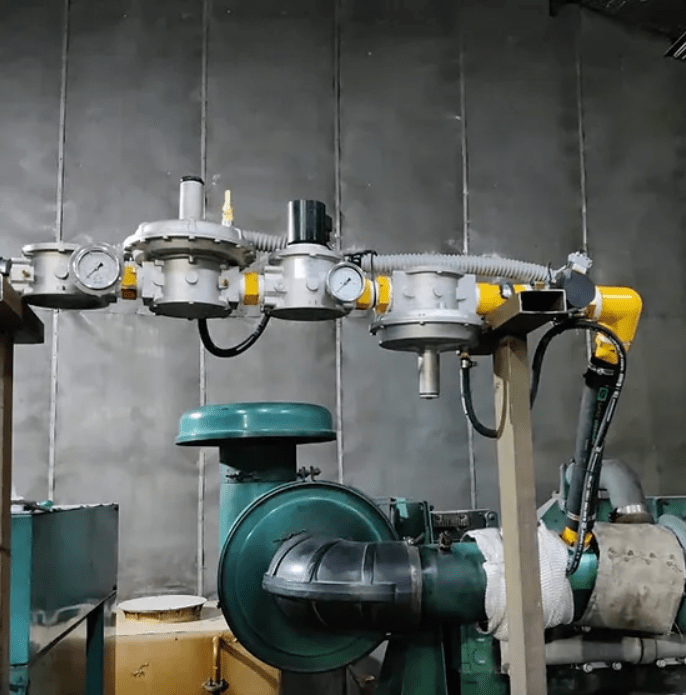

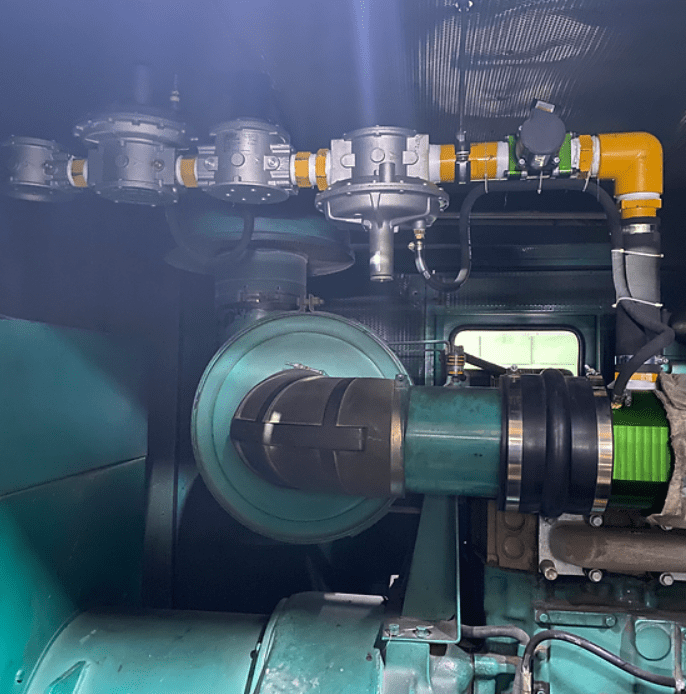

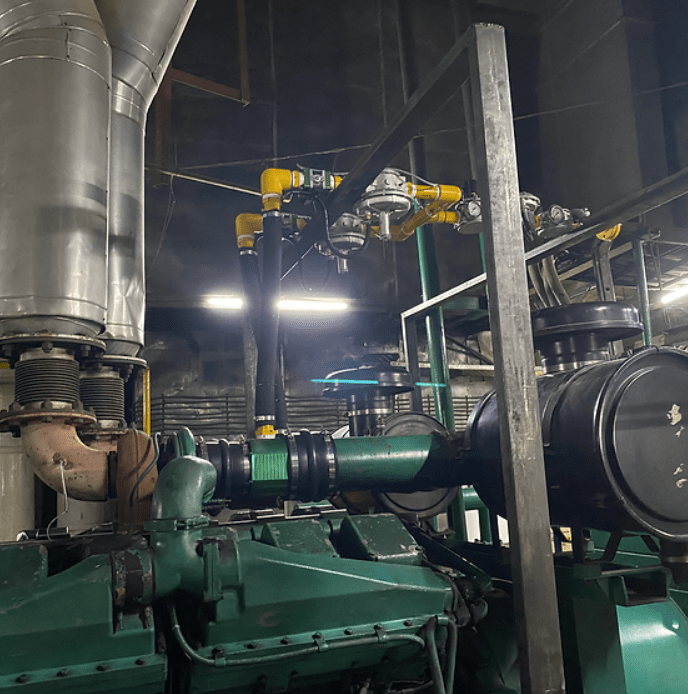

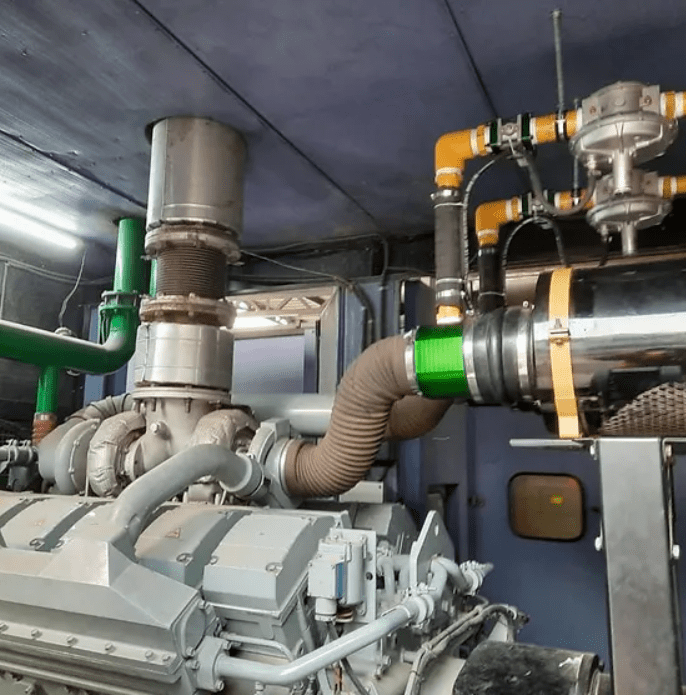

Some Retrofitted Dual Fuel (Diesel + CNG) Installations

Some Retrofitted Dual

Fuel (Diesel + CNG) Installations

Diesel + LPG

Dual Fuel Conversion

Available Now!

Power-up your Diesel Generator with cooking GAS and save up to 30% in Overall Genset OpEx + Diesel Fueling Cost

Diesel + LPG

Dual Fuel Conversion

(Also Available)

Power-up your Diesel Generator with cooking GAS and save up to 30% in Overall Genset OpEx + Diesel Fueling Cost

Advantages of GasGen Dual Fuel Conversion

Lower Operating Costs

Up to 30% – 50% savings on overall genset OpEx and diesel fueling cost as natural gas is cheaper than diesel especially CNG. LPG or CNG as a source of fueling maintains cleaner engine system and lubricants while also extending the servicing interval of gensets, thus reducing the maintenance and operational expenses (OpEx). These would result in significant cost savings for businesses and organizations that rely on diesel generators for backup power or primary power generation.

Environmental Benefits

Due to cleaner burning characteristics of Natural Gases used as fuel compared to diesel-only, this reduces the emission of air pollutants such as nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2) that are harmful both to human health and the environment. This conversion can help reduce the carbon print, thus the environmental impact of power generators. Hence, this would result in cleaner generator exhausts.

Technical Benefits

Retrofit systems can be installed in the field quickly, minimizing engine downtime. No major modifications are made to the core engine configuration or to the factory fuel management system. With the engine’s main fuel becoming gaseous fuel rather than diesel and the electronic control system maximizing fuel efficiency, installing an alternative fuel system enables the on-site diesel supply to last much longer, extending engine uptime without compromising performance.

No Power/Efficiency loss

After conversion, there is no difference in the existing specific power output of the genset compared to the previous diesel-only genset. The output remains the same and with increase in efficiency.

Flexibility

Gensets that have been converted to Dual Fuel exhibit diesel-like performance in critical areas such as efficiency, stability and load acceptance. And in case of non-availability of gas or a faulty Dual Fuel controller, the mechanism would automatically shut down and the genset would be switched to run on diesel only mode.

Extended Run Time

It can extend the generator runtime by automatically switching between fuels when one runs low.

Diesel + Gas System Solutions

for Power Generators and Other Diesel Engines

Agricultural Machineries l Heavy Trucks l Construction Machineries

Works With All Diesel Generator Brands

Diesel + Gas

System Solutions

for Power Generators and other Diesel Engines

Heavy Trucks

Agricultural Machineries

Construction Machineries

Works With All Diesel Generator Brands

Gas Fuel Storage

An optimally working Dual Fuel System of a converted diesel generator requires that one provides a reliable or dedicated source of natural gas supply setup to avoid disruption. This may involve installing a dedicated natural gas pipeline (PNG) for an uninterrupted gas supply or situate cascaded Compressed Natural Gas (CNG) or Liquefied Petroleum Gas (LPG) storage tanks close and connected to the targeted generator.